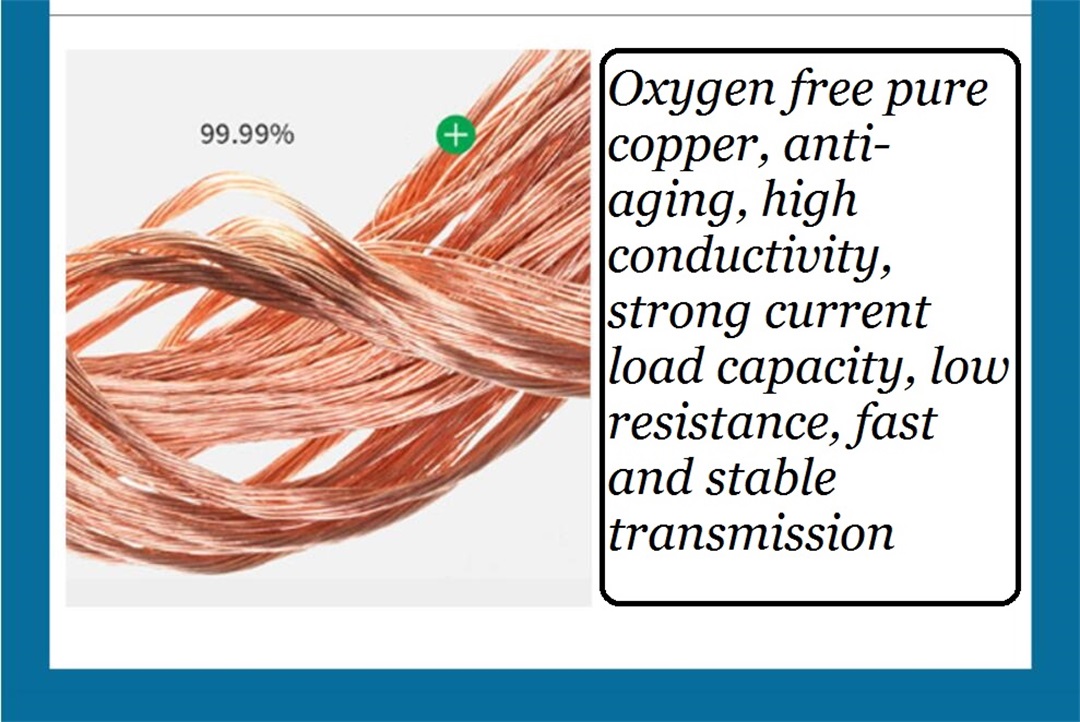

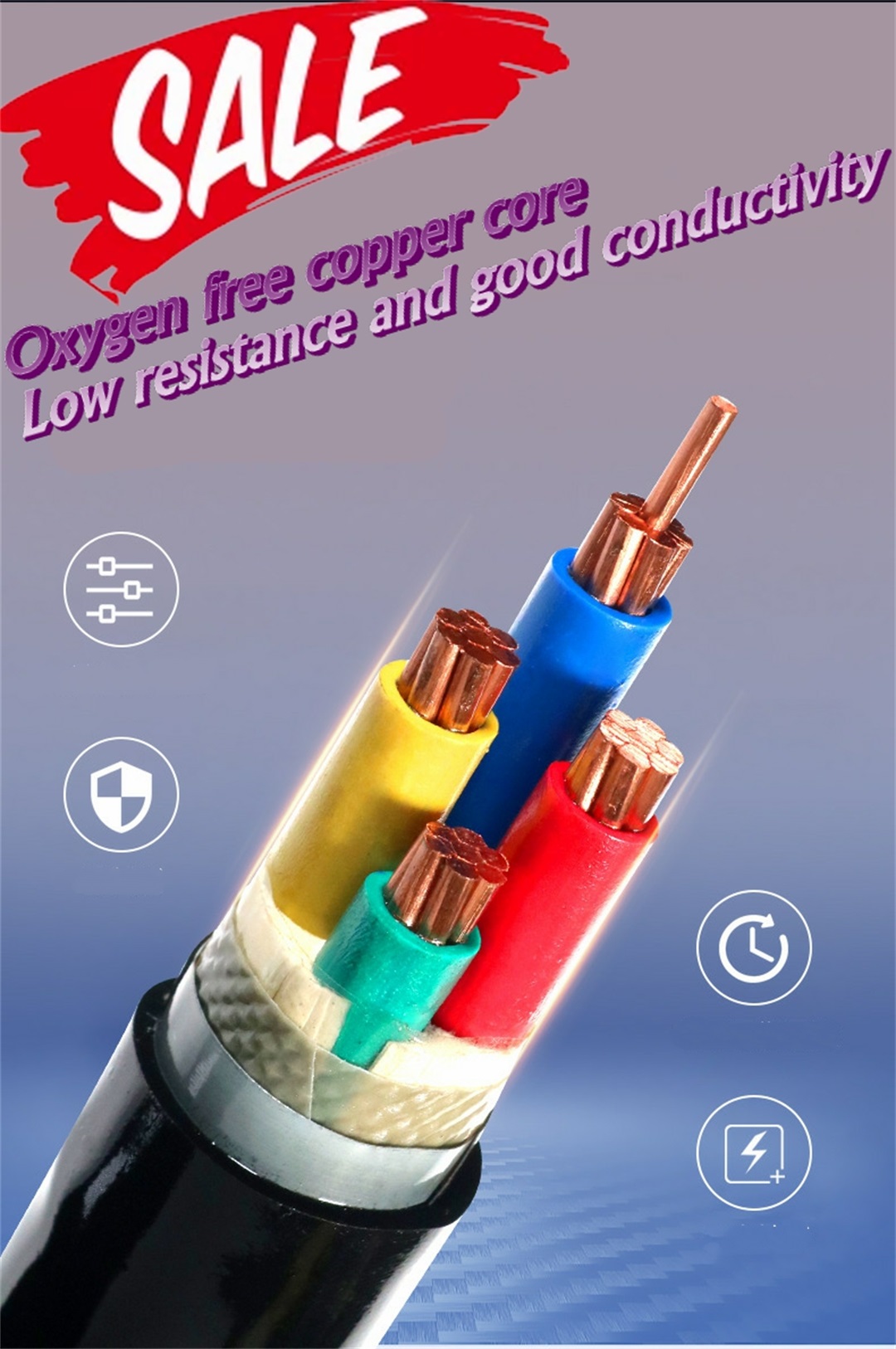

Product features: Cross linked polyethylene insulated power cables have excellent thermal mechanical properties, excellent electrical and chemical corrosion resistance, simple structure, light weight, and no drop limit for laying. The cable insulation adopts cross-linked polyethylene, which is a chemical method to convert linear molecular polyethylene into cross-linked polyethylene with three-dimensional network structure, thereby greatly improving the mechanical properties of polyethylene and maintaining excellent electrical properties. Product advantages: 1. Small land occupation Generally, it is buried in the soil or laid indoors, in ditches and tunnels. The insulation distance between lines is small, without poles and towers. It occupies less land and basically does not occupy space on the ground 2. High reliability, less affected by climatic conditions and surrounding environment, stable transmission performance and high reliability 3. It has more favorable conditions for the development of ultra-high voltage and large capacity, such as low temperature and superconducting power cables 4. Large distributed capacitance 5. Less maintenance work 6. The possibility of electric shock is low

Product features: Cross linked polyethylene insulated power cables have excellent thermal mechanical properties, excellent electrical and chemical corrosion resistance, simple structure, light weight, and no drop limit for laying. The cable insulation adopts cross-linked polyethylene, which is a chemical method to convert linear molecular polyethylene into cross-linked polyethylene with three-dimensional network structure, thereby greatly improving the mechanical properties of polyethylene and maintaining excellent electrical properties. Product advantages: 1. Small land occupation Generally, it is buried in the soil or laid indoors, in ditches and tunnels. The insulation distance between lines is small, without poles and towers. It occupies less land and basically does not occupy space on the ground 2. High reliability, less affected by climatic conditions and surrounding environment, stable transmission performance and high reliability 3. It has more favorable conditions for the development of ultra-high voltage and large capacity, such as low temperature and superconducting power cables 4. Large distributed capacitance 5. Less maintenance work 6. The possibility of electric shock is low

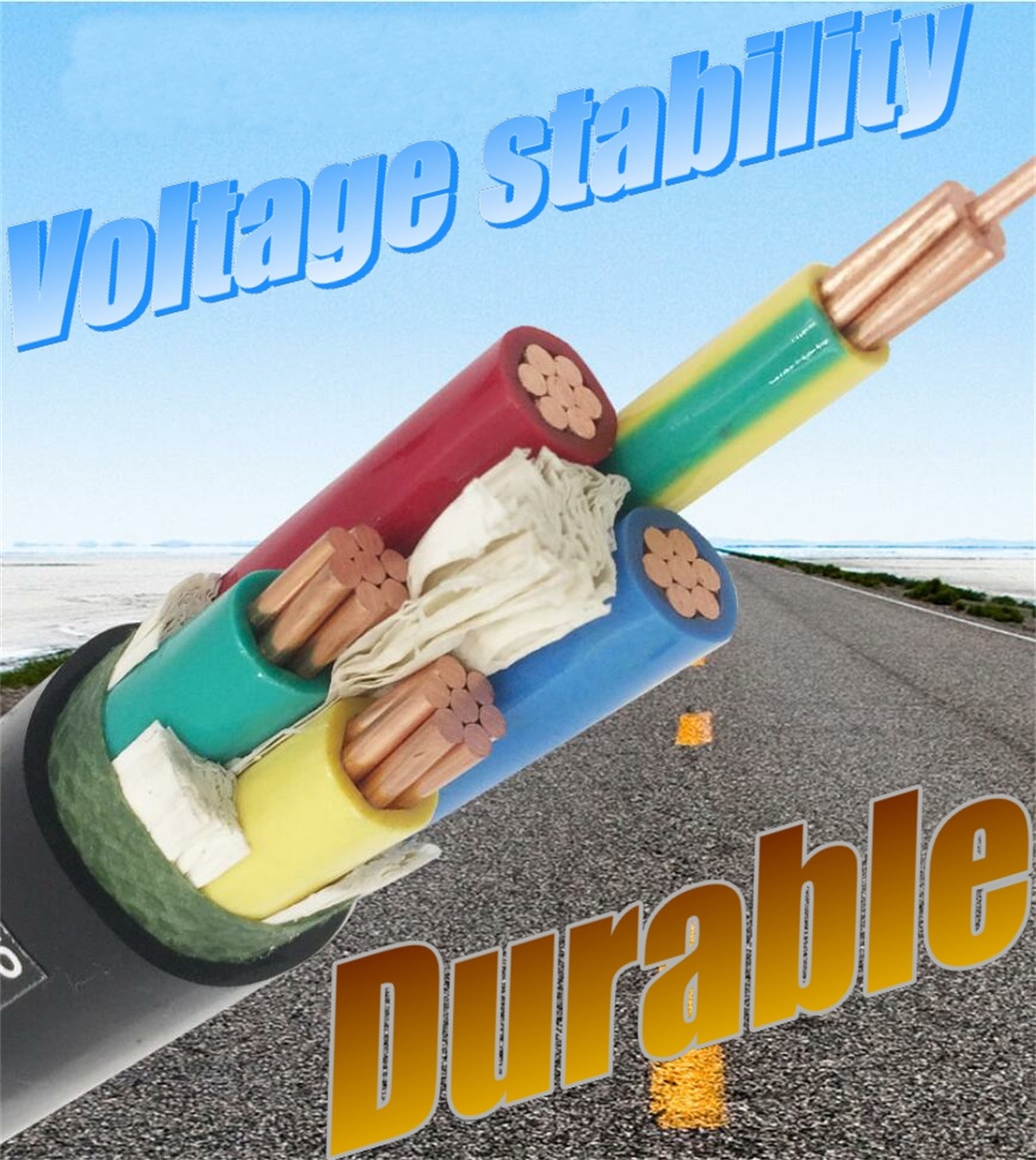

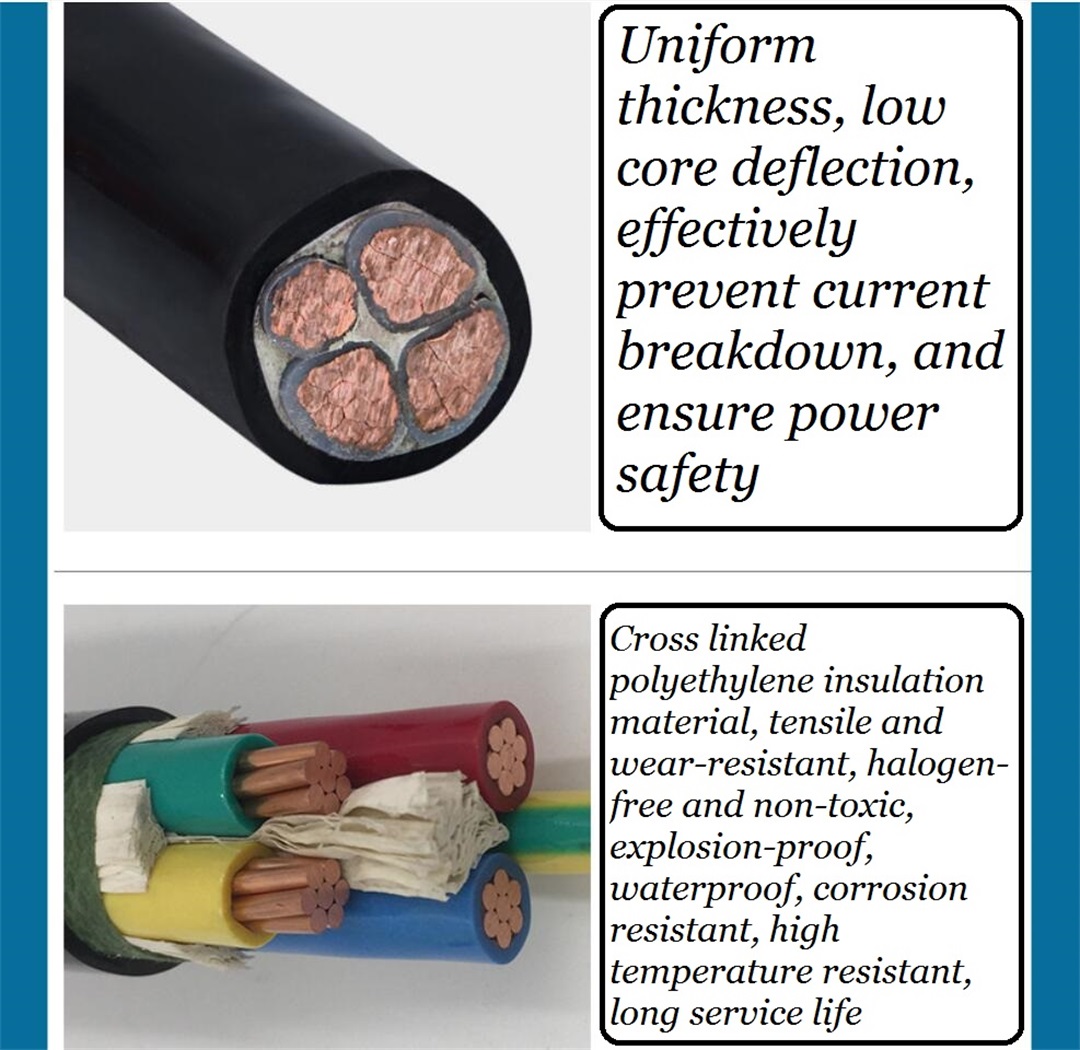

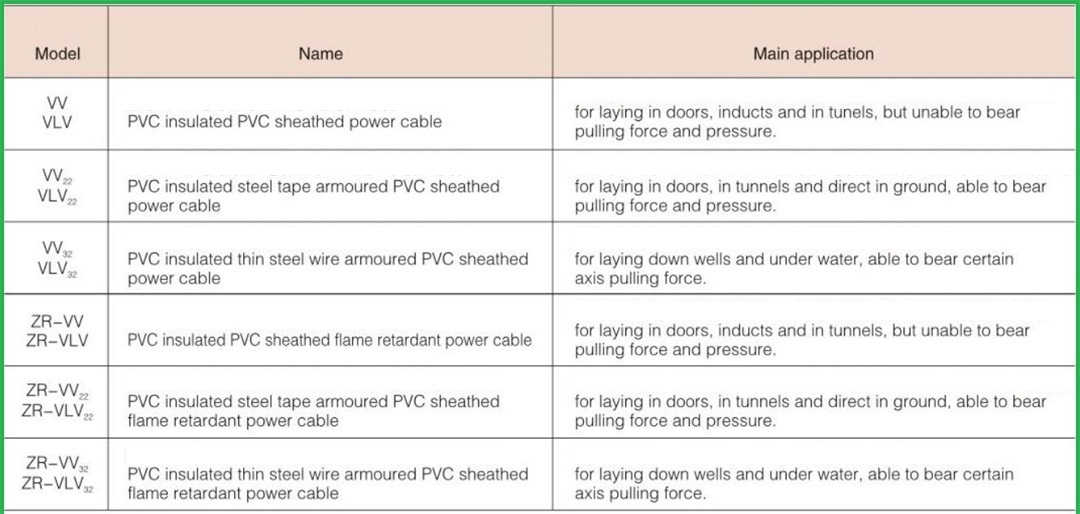

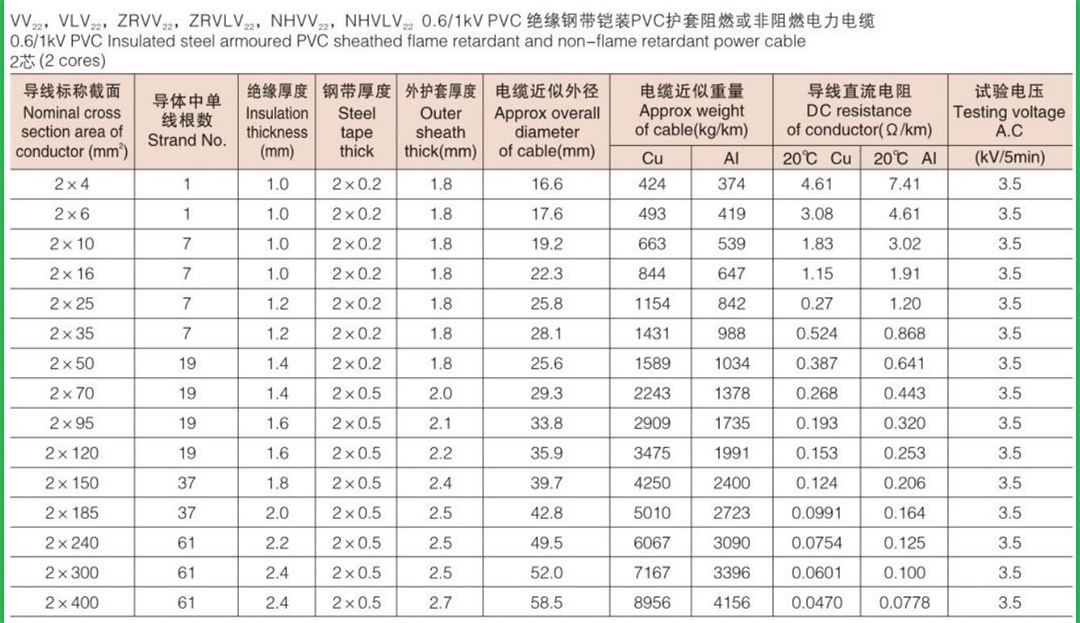

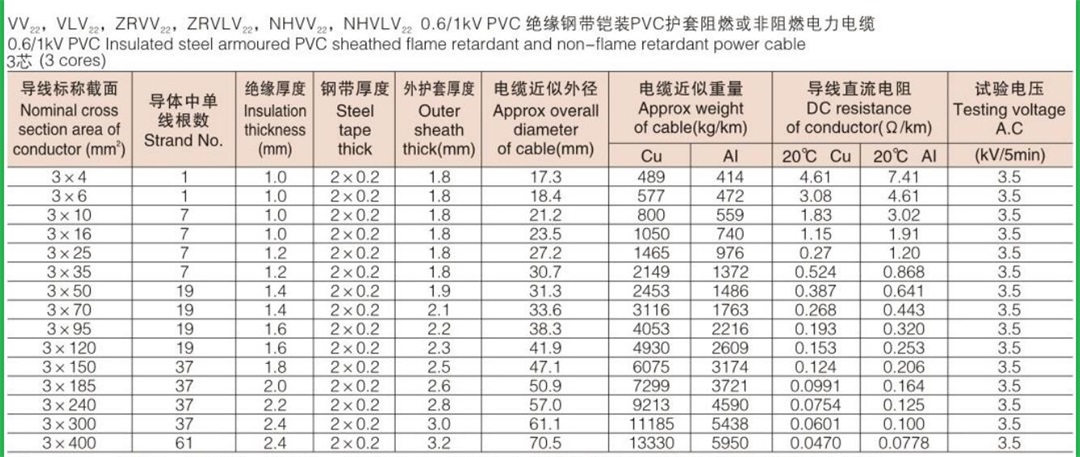

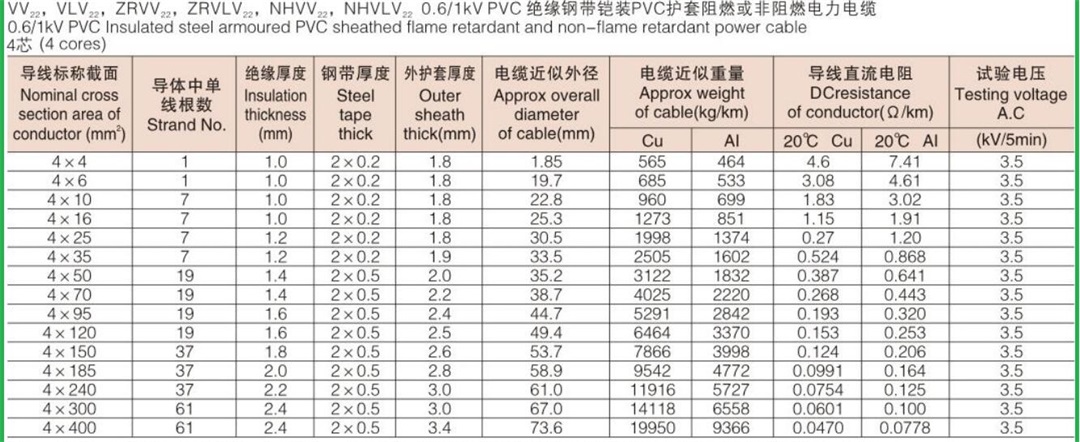

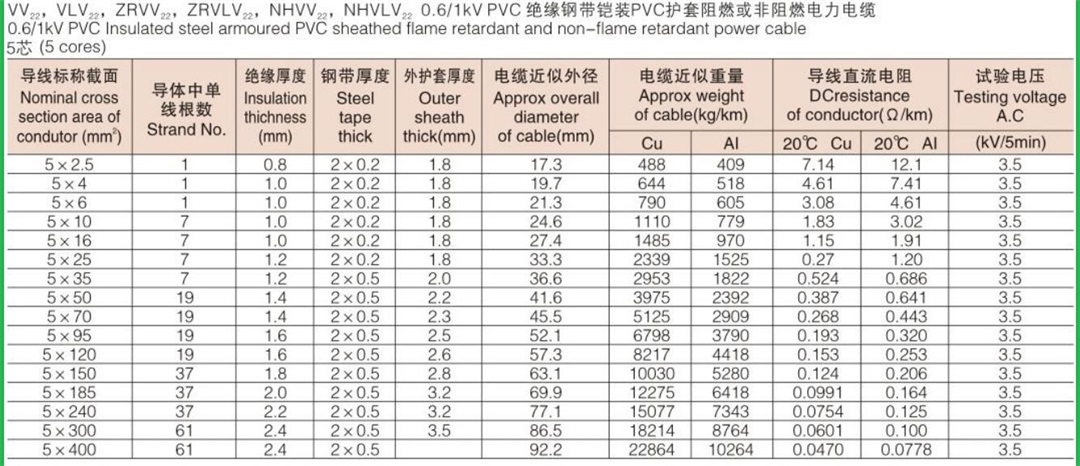

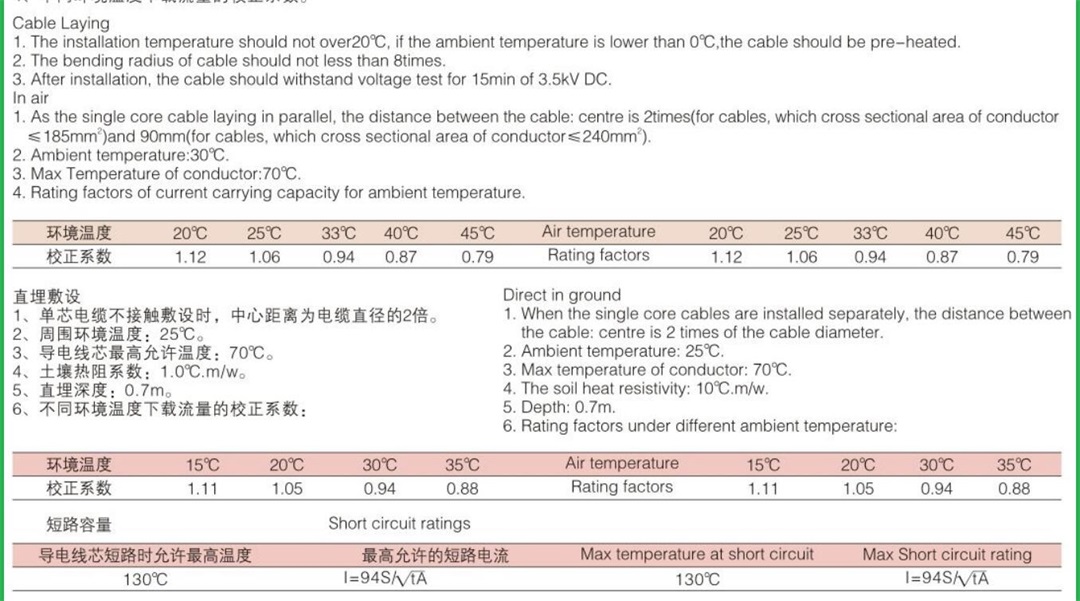

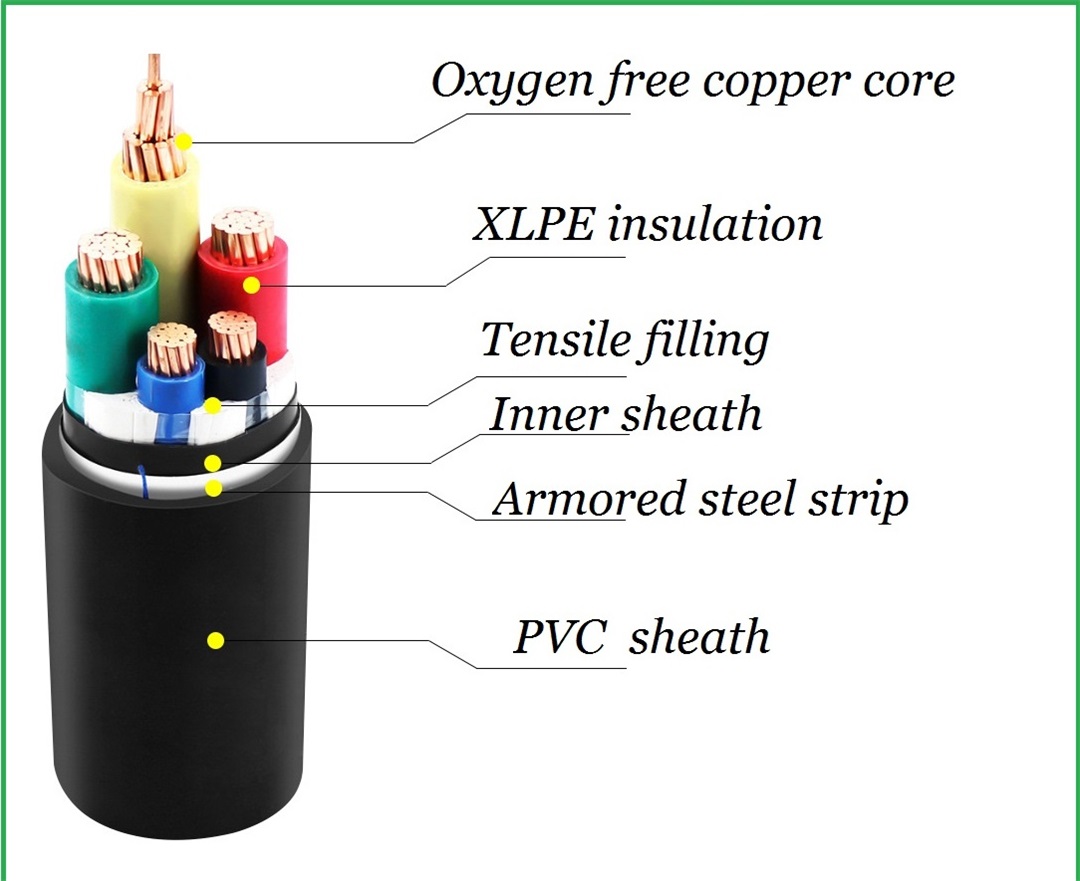

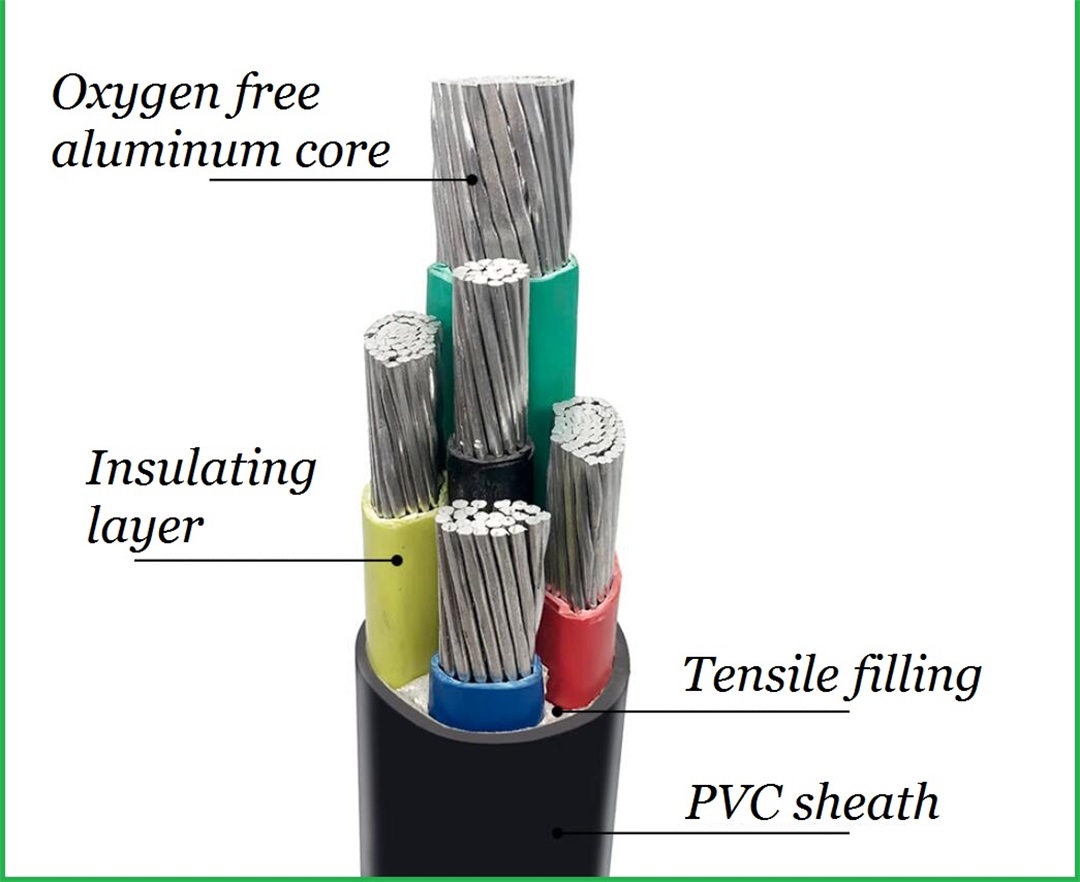

Product structure: The inner and outer components are conductor, insulation layer, filling layer, (steel strip layer) and sheath layer. Nowadays, the most commonly used conductor material on the market is certainly copper conductor; The insulating layer and outer sheath are made of PVC, namely PVC plastic; The filling layer is generally made of some soft nylon materials to prevent direct contact and extrusion between conductors inside the cable; VV cable with steel tape armouring is VV22 cable. The role of steel tape armouring is compression resistance and can be used for burial. Use properties: 1. The long-term allowable working temperature of cable conductor is more than 70 ℃. 2. In case of short circuit (the longest duration shall not exceed 5 seconds), the maximum temperature of cable conductor shall not exceed 165 ℃. 3. The cable is not limited by the laying drop, and the ambient temperature during cable laying is not lower than 0 ℃. 4. Good chemical stability, acid, alkali, salt, oil and organic solvent resistance, and flame resistance. 5. Light weight, good bending performance, simple and convenient installation and maintenance.

Product structure: The inner and outer components are conductor, insulation layer, filling layer, (steel strip layer) and sheath layer. Nowadays, the most commonly used conductor material on the market is certainly copper conductor; The insulating layer and outer sheath are made of PVC, namely PVC plastic; The filling layer is generally made of some soft nylon materials to prevent direct contact and extrusion between conductors inside the cable; VV cable with steel tape armouring is VV22 cable. The role of steel tape armouring is compression resistance and can be used for burial. Use properties: 1. The long-term allowable working temperature of cable conductor is more than 70 ℃. 2. In case of short circuit (the longest duration shall not exceed 5 seconds), the maximum temperature of cable conductor shall not exceed 165 ℃. 3. The cable is not limited by the laying drop, and the ambient temperature during cable laying is not lower than 0 ℃. 4. Good chemical stability, acid, alkali, salt, oil and organic solvent resistance, and flame resistance. 5. Light weight, good bending performance, simple and convenient installation and maintenance.