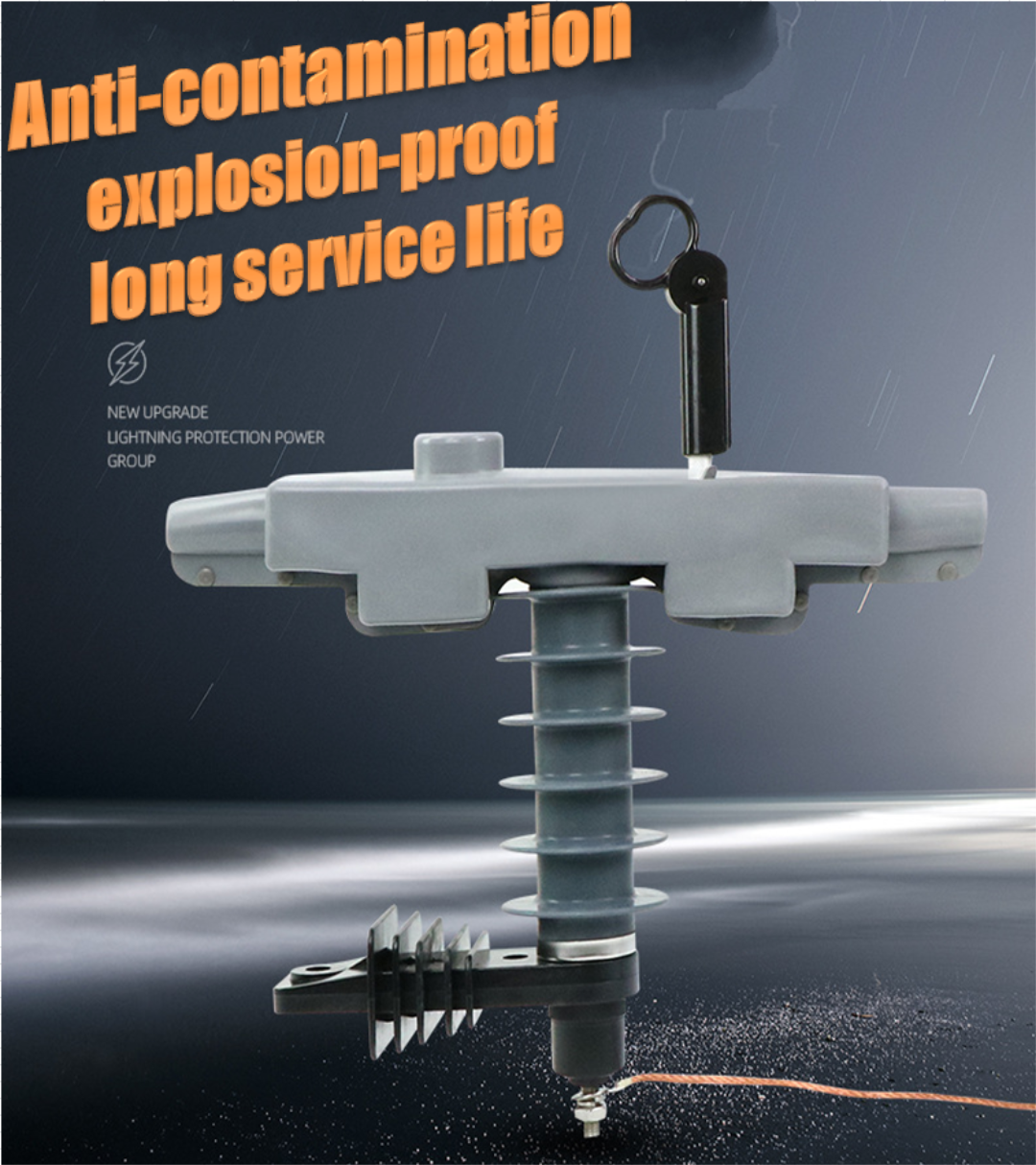

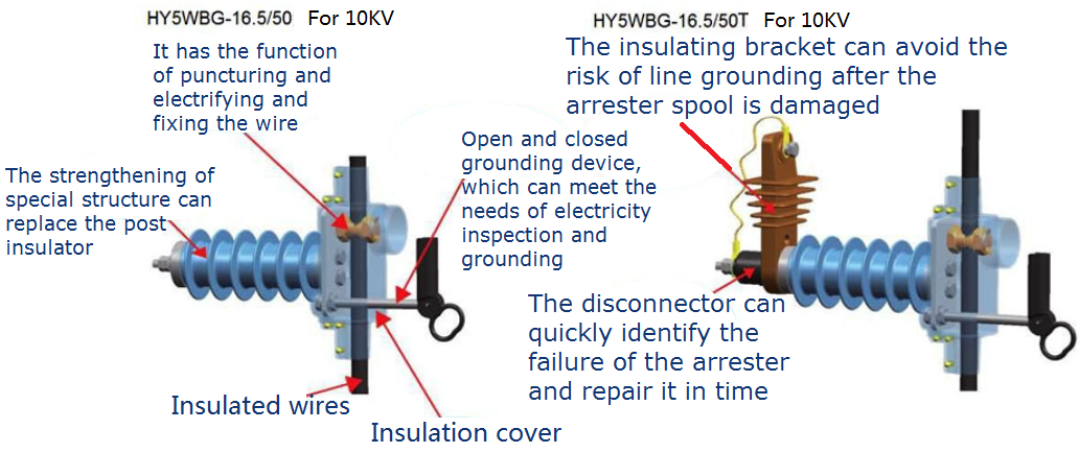

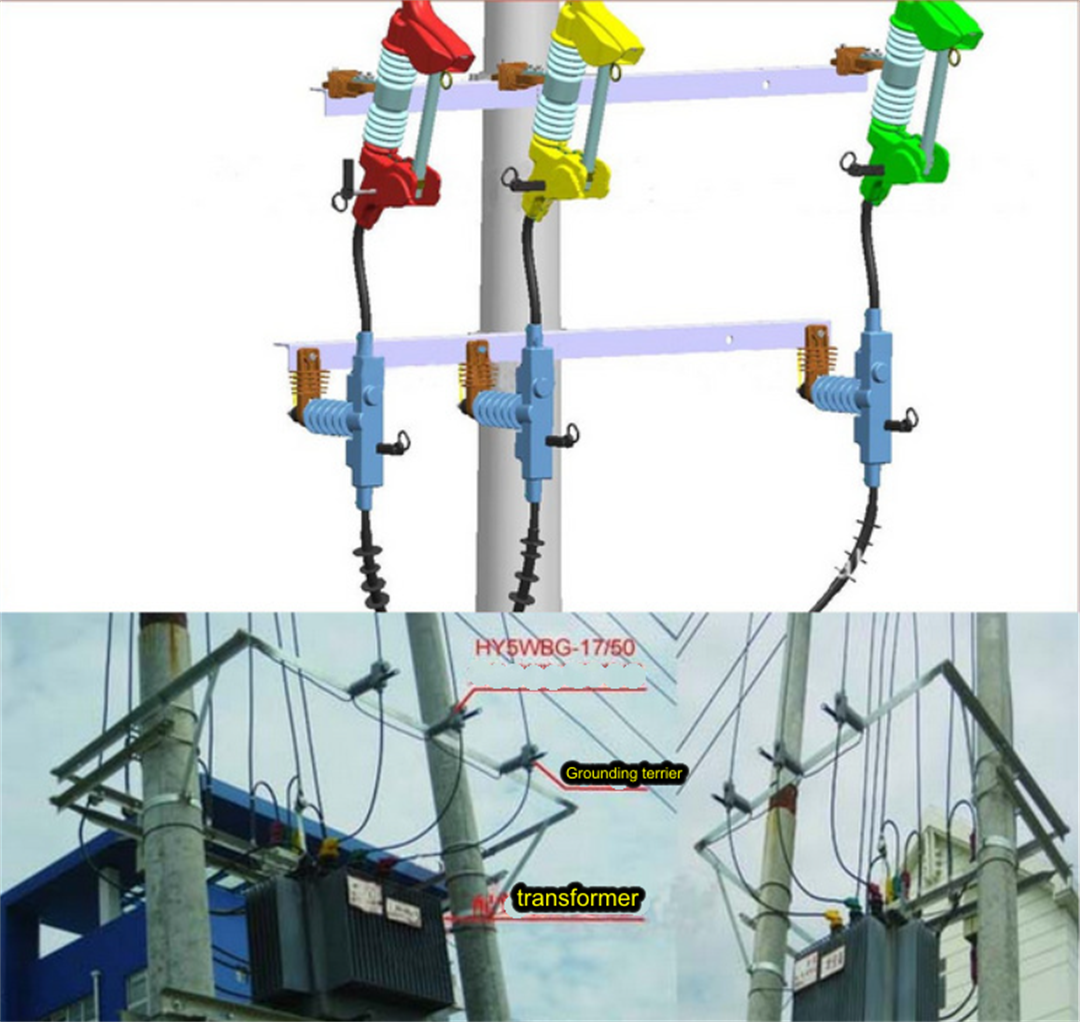

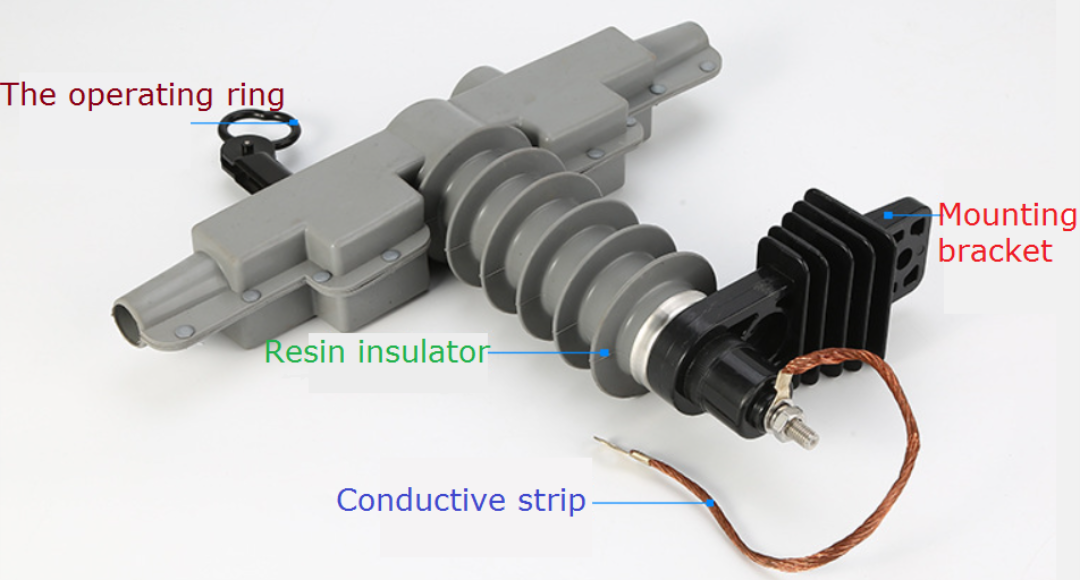

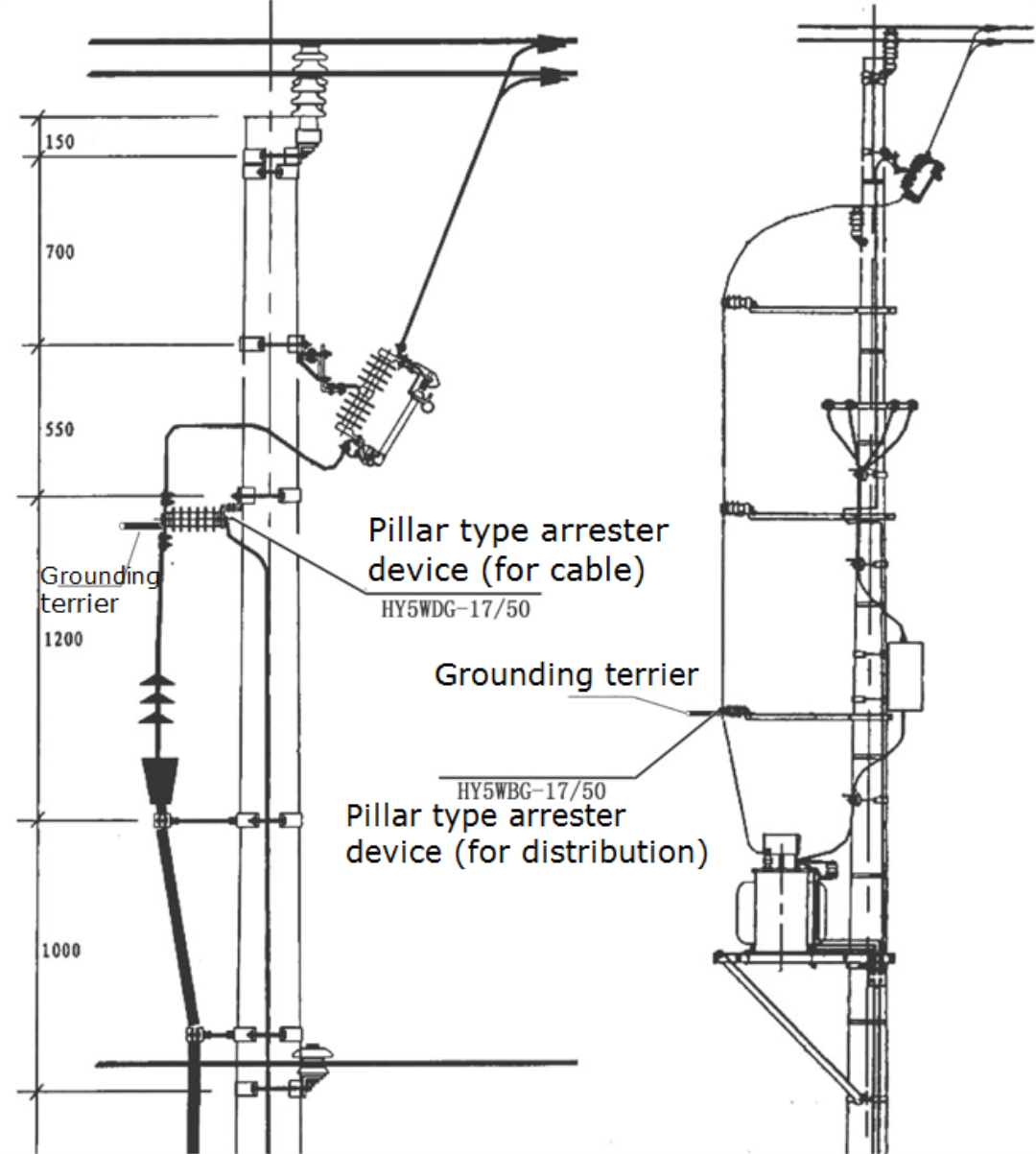

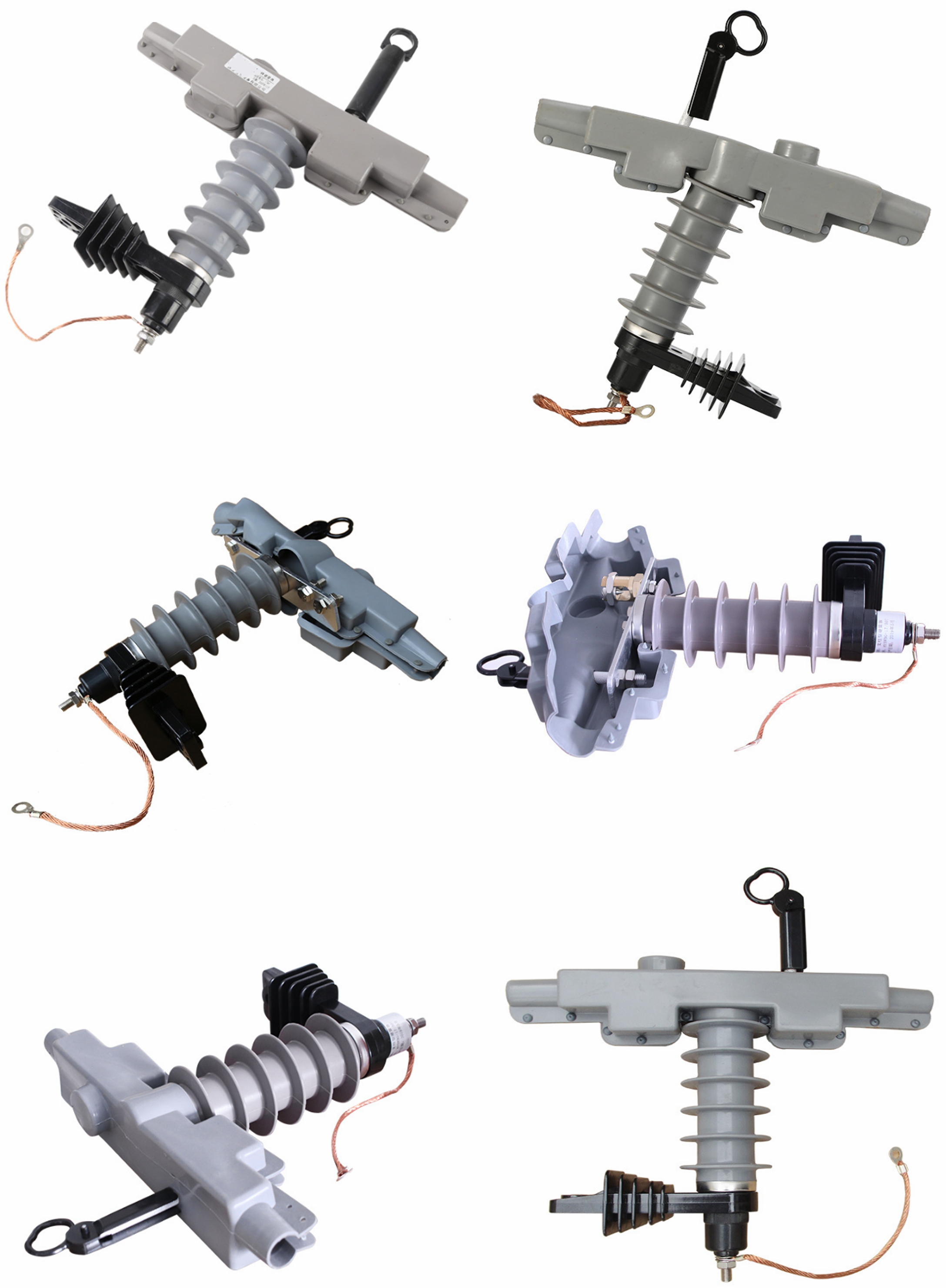

1. The core body and jacket of the arrester are molded into a compact whole without a cavity, which eliminates the moisture absorption caused by breathing and fundamentally eliminates the accident caused by the damping of the arrester chip. 2. The inside of the arrester adopts a special strengthening structure, which makes it have good mechanical properties and can also be used as an insulator 3. The synthetic jacket of the arrester is made of silicone rubber material, which makes it have strong anti-pollution performance and good explosion-proof performance. In addition, light weight and long service life 4. The arresters are designed and produced according to the class III heavy pollution resistance. The minimum creepage ratio of the insulating jacket is 25mm/KV, and the creepage distance is 320mm. 5. The overall structure of the arrester is optimized and has a combined function. a. It has both grounding stems, which can meet the needs of electricity inspection and grounding, and can simplify the tower installation b. The special reinforcement structure makes it have good mechanical properties and can double as a pillar insulator c. The connection terminal block can segment the cable fault, reduce the power failure range, and has the function of breaking the knife switch d. The use of full insulation design can effectively avoid the occurrence of accidents such as external force damage 6. The arrester device has the function of supporting pillars, connecting terminal busbar wiring, and electrical inspection and grounding. The connecting terminal busbar can segment cable faults, reduce the scope of power outages, and has the function of segmenting a knife switch.

1. The core body and jacket of the arrester are molded into a compact whole without a cavity, which eliminates the moisture absorption caused by breathing and fundamentally eliminates the accident caused by the damping of the arrester chip. 2. The inside of the arrester adopts a special strengthening structure, which makes it have good mechanical properties and can also be used as an insulator 3. The synthetic jacket of the arrester is made of silicone rubber material, which makes it have strong anti-pollution performance and good explosion-proof performance. In addition, light weight and long service life 4. The arresters are designed and produced according to the class III heavy pollution resistance. The minimum creepage ratio of the insulating jacket is 25mm/KV, and the creepage distance is 320mm. 5. The overall structure of the arrester is optimized and has a combined function. a. It has both grounding stems, which can meet the needs of electricity inspection and grounding, and can simplify the tower installation b. The special reinforcement structure makes it have good mechanical properties and can double as a pillar insulator c. The connection terminal block can segment the cable fault, reduce the power failure range, and has the function of breaking the knife switch d. The use of full insulation design can effectively avoid the occurrence of accidents such as external force damage 6. The arrester device has the function of supporting pillars, connecting terminal busbar wiring, and electrical inspection and grounding. The connecting terminal busbar can segment cable faults, reduce the scope of power outages, and has the function of segmenting a knife switch.

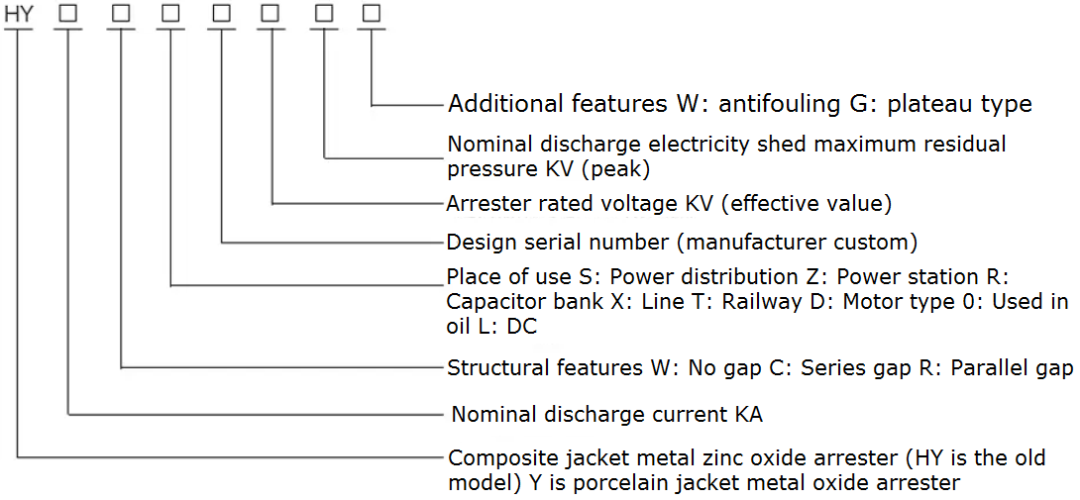

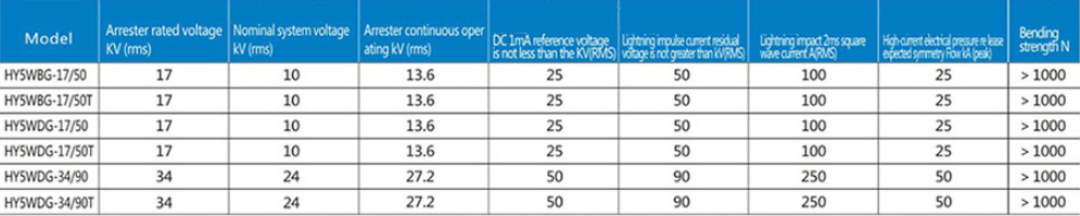

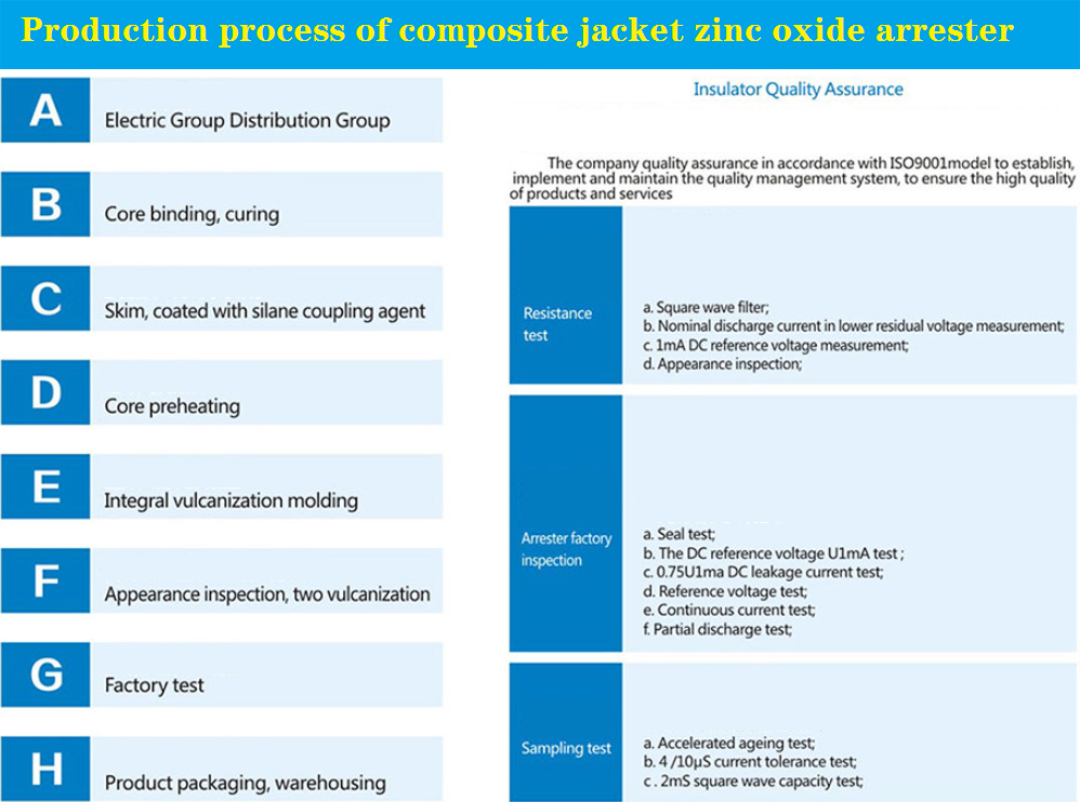

The production standard of the product is GB11032-2000 (eqv IEC60099-4:1991) "AC No-gap Metal Oxide Surge Arrester", JB/8952-2005 "Composite Jacket No-gap Metal Oxide Surge Arrester for AC System" 1. The arrester should be stored in a clean and dry room before installation and use. Must not be corroded by corrosive gases or liquids. 2. Before the arrester is put into operation, a preventive test should be carried out. After being put into operation, it should also be regularly (10KV and below arrester once every 5 years, 35KV and above arrester once every 2 years) Do the following test and compare with the data before operation with reference to the attached table: a. Measure the insulation resistance of the arrester b. Measure the DC 1mA voltage of the arrester c. Measure the leakage current of 0.75 times DC 1mA

The production standard of the product is GB11032-2000 (eqv IEC60099-4:1991) "AC No-gap Metal Oxide Surge Arrester", JB/8952-2005 "Composite Jacket No-gap Metal Oxide Surge Arrester for AC System" 1. The arrester should be stored in a clean and dry room before installation and use. Must not be corroded by corrosive gases or liquids. 2. Before the arrester is put into operation, a preventive test should be carried out. After being put into operation, it should also be regularly (10KV and below arrester once every 5 years, 35KV and above arrester once every 2 years) Do the following test and compare with the data before operation with reference to the attached table: a. Measure the insulation resistance of the arrester b. Measure the DC 1mA voltage of the arrester c. Measure the leakage current of 0.75 times DC 1mA