1. Each has the advantages of small size, light weight, and convenient transportation. 2. Each composite insulator has high mechanical strength, reliable structure, stable performance, and high safety margin to ensure safe operation of the circuit. 3. Each composite electrical insulator has superior performance, good hydrophobicity and mobility, and stain resistance 4. It has good anti-pollution flashover ability, and can operate safely in heavily polluted areas without manual cleaning, avoiding measurement zero point 5. Every A composite insulator has acid resistance, alkali resistance, heat aging resistance and capacitance resistance, good sealing performance, and can ensure insulation moisture and so on. 6. Anti-brittleness, earthquake strength, no brittle fracture accidents. Environmental conditions: 1) Indoor casing The ambient temperature is not higher than+40 ℃ and not lower than - 40 ℃ The altitude does not exceed 1000 m Monthly average value of relative humidity is not more than 90% The surrounding air shall be free from corrosive or obvious pollution such as combustible gas and water vapor No frequent violent vibration 2) Outdoor casing The ambient temperature shall not be higher than+40 ℃ and not lower than - 40 ℃; The altitude shall not exceed 1000 m; The wind speed is not more than 34m/s According to GB/T5582, the air pollution degree of the product's use environment is divided into four levels: I, II, III and IV; No frequent violent vibration

1. Each has the advantages of small size, light weight, and convenient transportation. 2. Each composite insulator has high mechanical strength, reliable structure, stable performance, and high safety margin to ensure safe operation of the circuit. 3. Each composite electrical insulator has superior performance, good hydrophobicity and mobility, and stain resistance 4. It has good anti-pollution flashover ability, and can operate safely in heavily polluted areas without manual cleaning, avoiding measurement zero point 5. Every A composite insulator has acid resistance, alkali resistance, heat aging resistance and capacitance resistance, good sealing performance, and can ensure insulation moisture and so on. 6. Anti-brittleness, earthquake strength, no brittle fracture accidents. Environmental conditions: 1) Indoor casing The ambient temperature is not higher than+40 ℃ and not lower than - 40 ℃ The altitude does not exceed 1000 m Monthly average value of relative humidity is not more than 90% The surrounding air shall be free from corrosive or obvious pollution such as combustible gas and water vapor No frequent violent vibration 2) Outdoor casing The ambient temperature shall not be higher than+40 ℃ and not lower than - 40 ℃; The altitude shall not exceed 1000 m; The wind speed is not more than 34m/s According to GB/T5582, the air pollution degree of the product's use environment is divided into four levels: I, II, III and IV; No frequent violent vibration

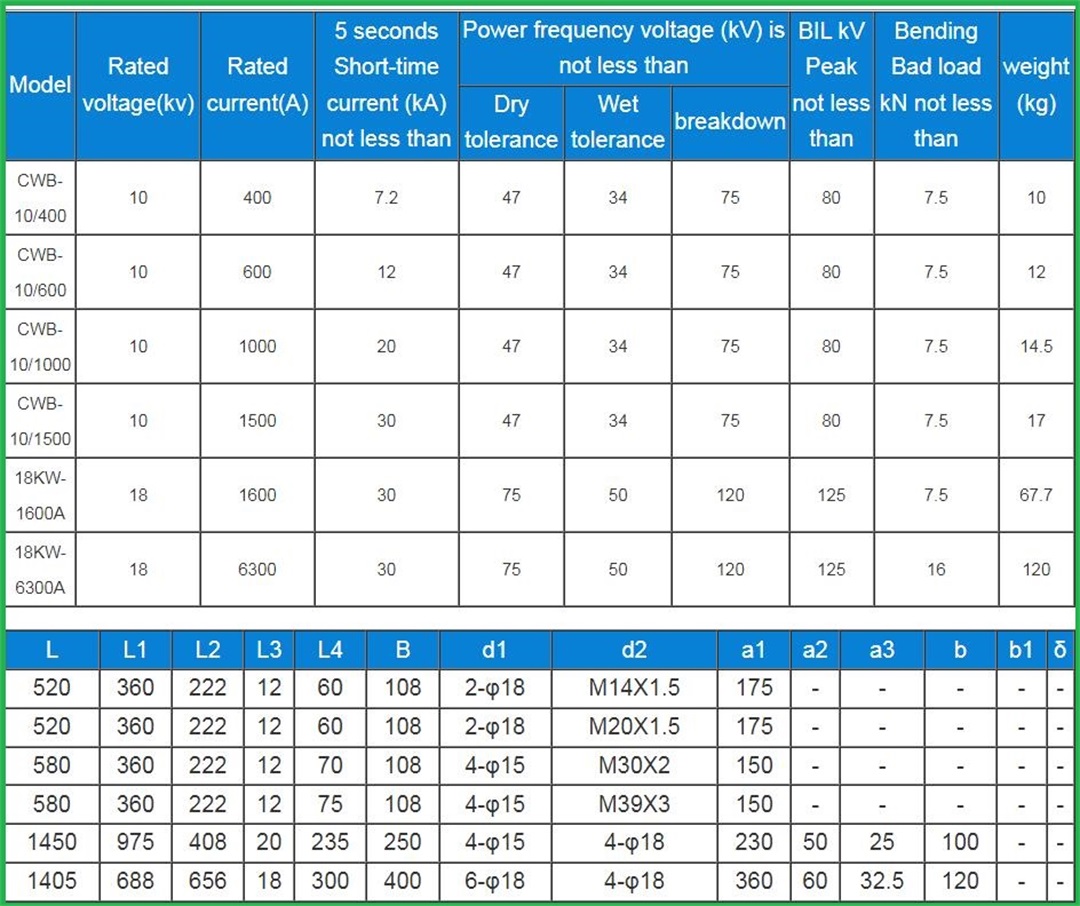

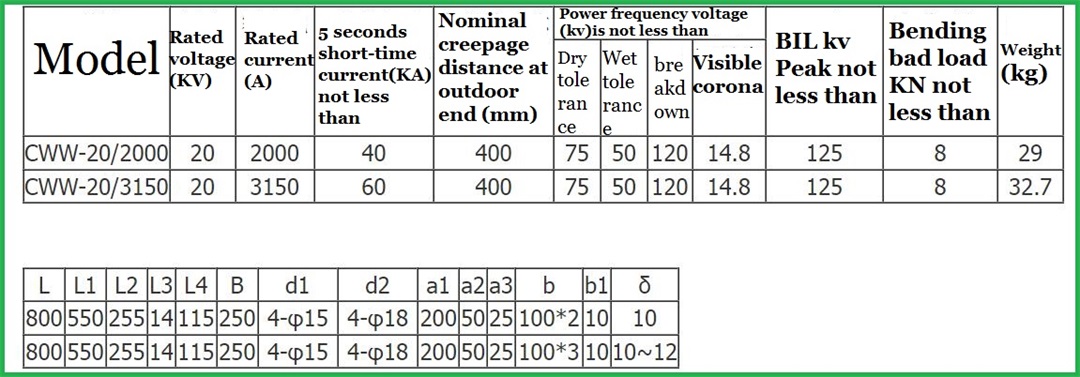

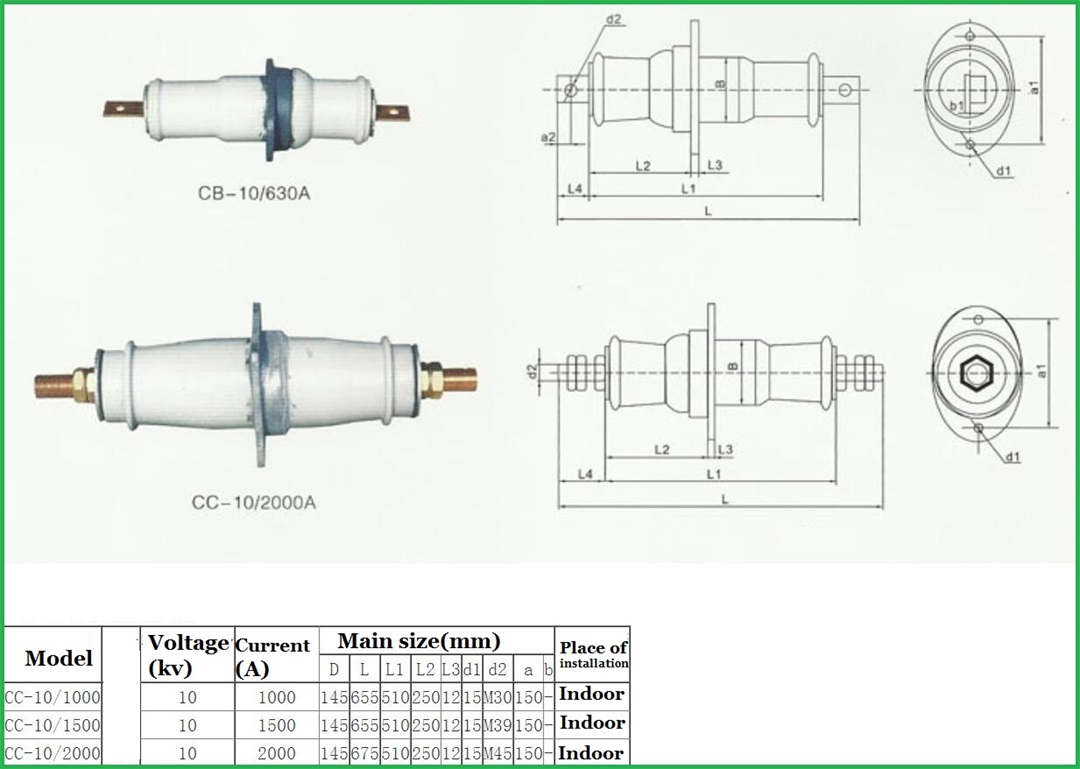

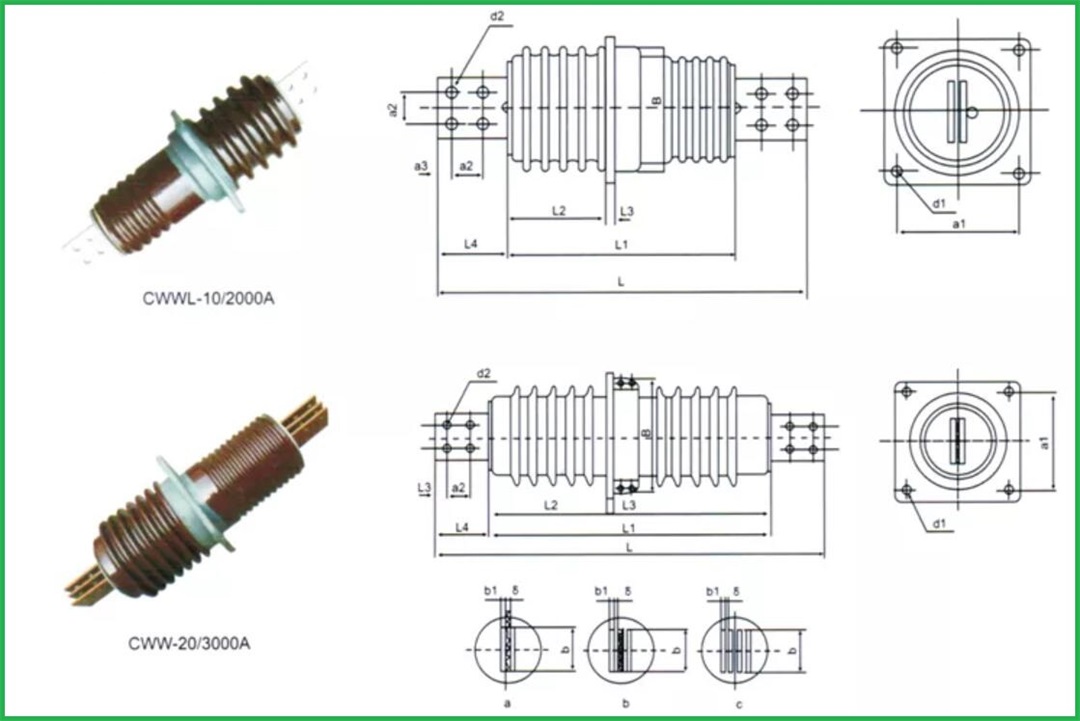

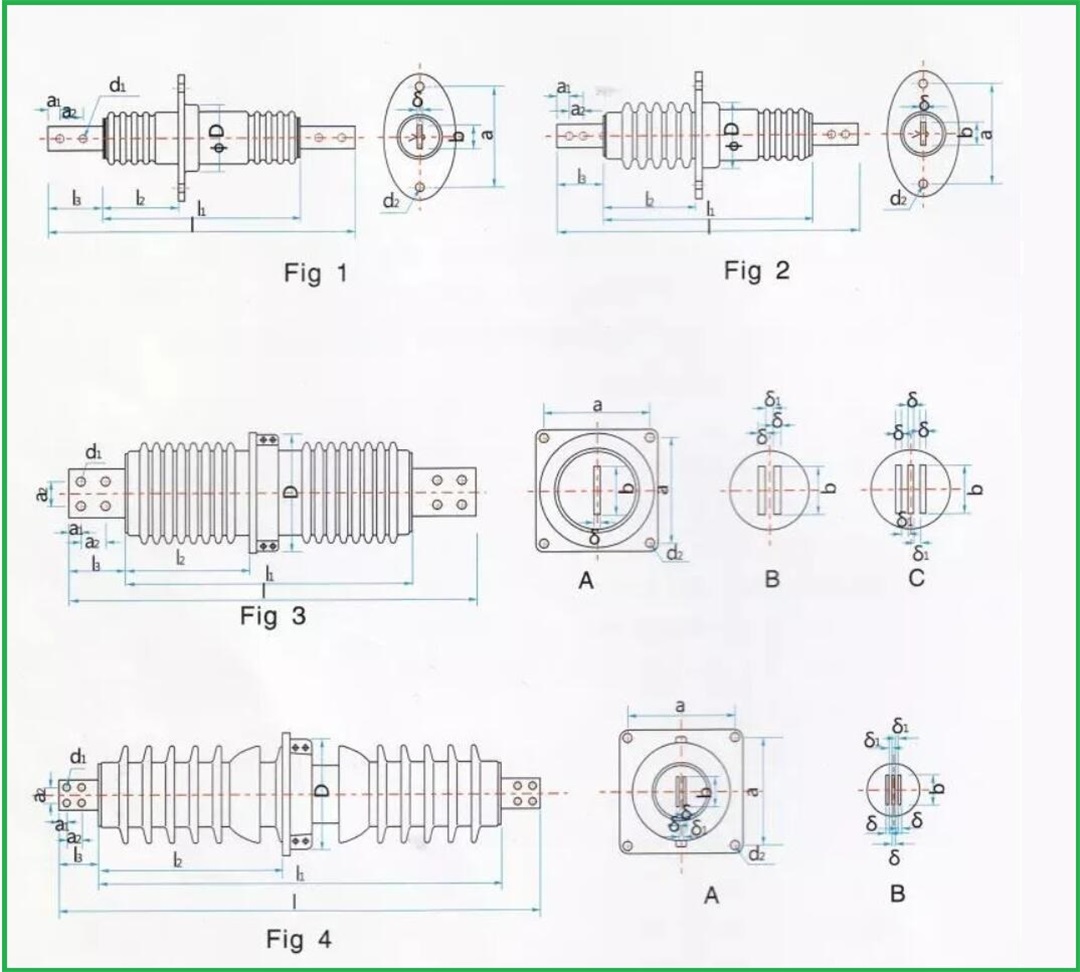

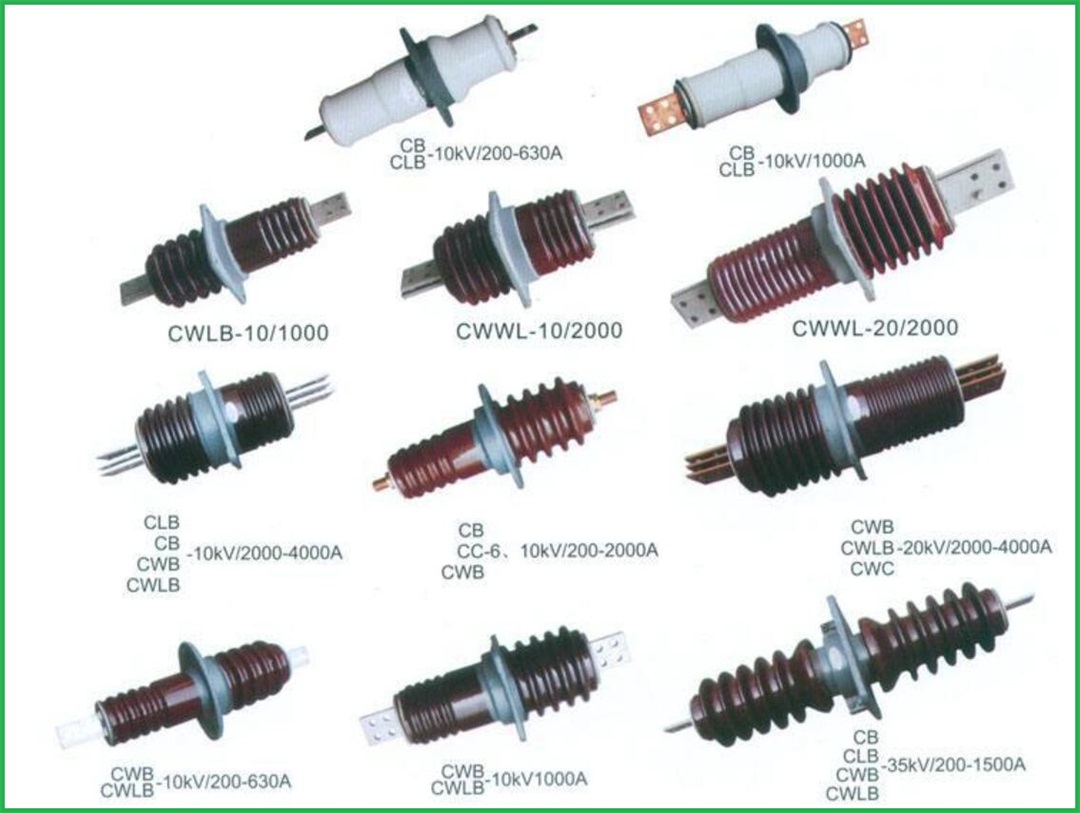

Use and classification: The casing is composed of porcelain parts, metal accessories, mounting flanges and conductive bars (rods). Wall-through porcelain bushings are used for power distribution devices and high-voltage electrical appliances in power stations and substations, for wires to pass through grounding partitions, walls or electrical equipment enclosures, and to support conductive parts to insulate them from the ground or the enclosure. Wall-through porcelain bushings can be divided into indoor and outdoor wall-through porcelain bushings according to their use environment. According to the different conductors passing through its center, it can be divided into busbar through-wall porcelain bushing, copper conductor through-wall porcelain bushing and aluminum conductor through-wall porcelain bushing. When the copper conductor is directly connected to the busbar, galvanic corrosion is easy to occur, and the temperature rise of the contact surface is too high, which will cause the joint to burn out and affect the life of the equipment. Therefore, copper-aluminum transition joints should be used, but it will bring trouble to the site construction. The casing can solve the above problems. Indoor and outdoor wall-through porcelain bushings are assembled from porcelain parts, conductive rods, metal accessories at both ends and mounting flanges. The busbar wall-through porcelain bushing is assembled from porcelain parts, metal accessories at both ends, busbar splint and mounting flange (the busbar splint is usually prepared by the user according to the size of the busbar). Instructions for installation and use: 1. The through-wall porcelain bushing is suitable for the distribution equipment of power stations and substations where the rated power frequency AC power is below 40.5kv, the ambient temperature of the installation site is -40°C~+40°C, and the altitude does not exceed 1000m. 2. Indoor wall bushings are not suitable for places where the enamel, metal accessories and cement adhesive of the bushing are damaged or are enough to reduce the electrical performance of the bushing. 3. If partial discharge occurs during the operation of the through-wall porcelain bushing, check whether there is any partial shedding of the aluminum sprayed layer at the flange or inner cavity of the porcelain bushing, and if so, take temporary pressure equalization measures in time. 4. The wall hole for installing the busbar through-wall porcelain bushing should be opened according to the large size of its flange reinforcement.

Use and classification: The casing is composed of porcelain parts, metal accessories, mounting flanges and conductive bars (rods). Wall-through porcelain bushings are used for power distribution devices and high-voltage electrical appliances in power stations and substations, for wires to pass through grounding partitions, walls or electrical equipment enclosures, and to support conductive parts to insulate them from the ground or the enclosure. Wall-through porcelain bushings can be divided into indoor and outdoor wall-through porcelain bushings according to their use environment. According to the different conductors passing through its center, it can be divided into busbar through-wall porcelain bushing, copper conductor through-wall porcelain bushing and aluminum conductor through-wall porcelain bushing. When the copper conductor is directly connected to the busbar, galvanic corrosion is easy to occur, and the temperature rise of the contact surface is too high, which will cause the joint to burn out and affect the life of the equipment. Therefore, copper-aluminum transition joints should be used, but it will bring trouble to the site construction. The casing can solve the above problems. Indoor and outdoor wall-through porcelain bushings are assembled from porcelain parts, conductive rods, metal accessories at both ends and mounting flanges. The busbar wall-through porcelain bushing is assembled from porcelain parts, metal accessories at both ends, busbar splint and mounting flange (the busbar splint is usually prepared by the user according to the size of the busbar). Instructions for installation and use: 1. The through-wall porcelain bushing is suitable for the distribution equipment of power stations and substations where the rated power frequency AC power is below 40.5kv, the ambient temperature of the installation site is -40°C~+40°C, and the altitude does not exceed 1000m. 2. Indoor wall bushings are not suitable for places where the enamel, metal accessories and cement adhesive of the bushing are damaged or are enough to reduce the electrical performance of the bushing. 3. If partial discharge occurs during the operation of the through-wall porcelain bushing, check whether there is any partial shedding of the aluminum sprayed layer at the flange or inner cavity of the porcelain bushing, and if so, take temporary pressure equalization measures in time. 4. The wall hole for installing the busbar through-wall porcelain bushing should be opened according to the large size of its flange reinforcement.